This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Call us on 01634 729 690.

Client: Advance Air Limited

Project: The Coliseum, JD Wetherspoons Abergavenny

Duration: 3 months from initial enquiry to installation

Objective Decarbonisation

The world is moving towards decarbonising (Net Zero) and a more sustainable future through the use of renewable energy. Generating renewable energy creates far lower emissions than burning fossil fuels. Transitioning from fossil fuels, which currently account for the lion’s share of emissions, to renewable energy is key to addressing the climate crisis.

At ece uk we are able to offer a ventilation system that not only reduces CO2 but will help improve future profit by no longer paying energy companies to burn a fossil fuel (Gas) and in turn use less electricity.

Our aim is to reduce the use of natural gas and electricity by replacing it with high efficiency energy recovery.

The primary goal of this project was to enhance energy efficiency, reduce carbon emissions and achieve cost savings for Wetherspoons pub chain. This was accomplished by utilizing a plate heat exchanger and a 3-way air mixing plenum to preheat incoming air. By reducing reliance on electric and gas heaters, the system effectively maintains comfortable indoor temperatures, lowers operational costs, and minimizes energy consumption by lowering the fan speed to 80% and utilizing a Plate Heat Exchanger (PHE) at peak occupancy and a 3-Way Air Mix with low occupancy.

This was further described in our original case study Decarbonisation, Sustainability and Increased Profitability through Energy Recovery Air Handling Units.

Make an enquiry for your air handling unit

Contact out team today and discuss your fresh air needs with our team. Call 01634 729 690, send an email to sales@eceuk.com, or make an enquiry through our form.

Design and Implementation

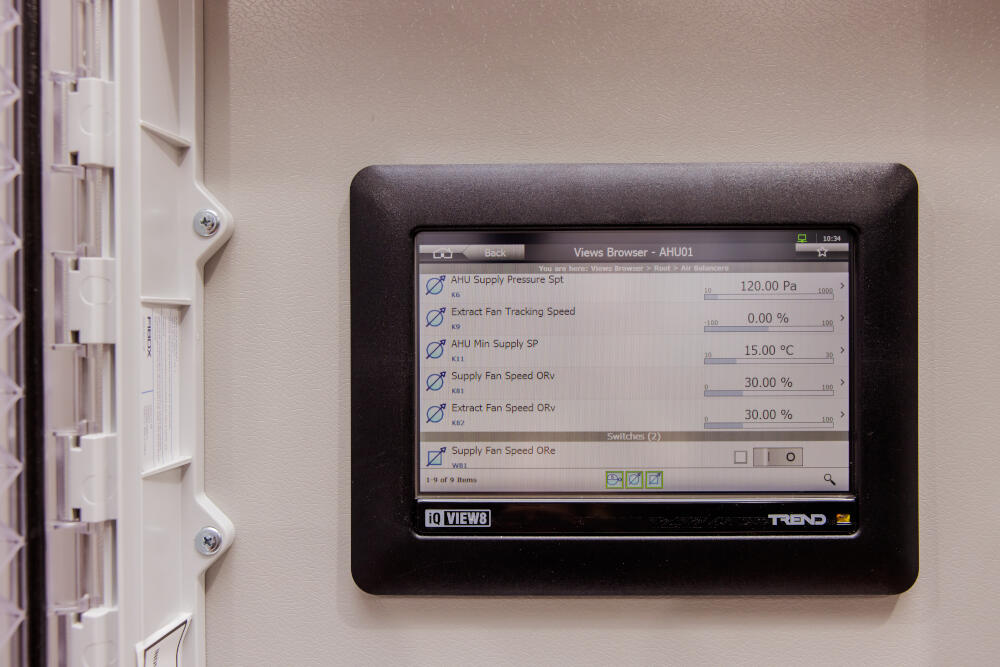

The AHU system incorporates a plate heat exchanger for heat recovery and a 3-way air mixing plenum for temperature regulation. These components work in conjunction with a CO₂ monitoring system, providing energy-efficient temperature control based on occupancy levels.

CO₂ Monitoring System:

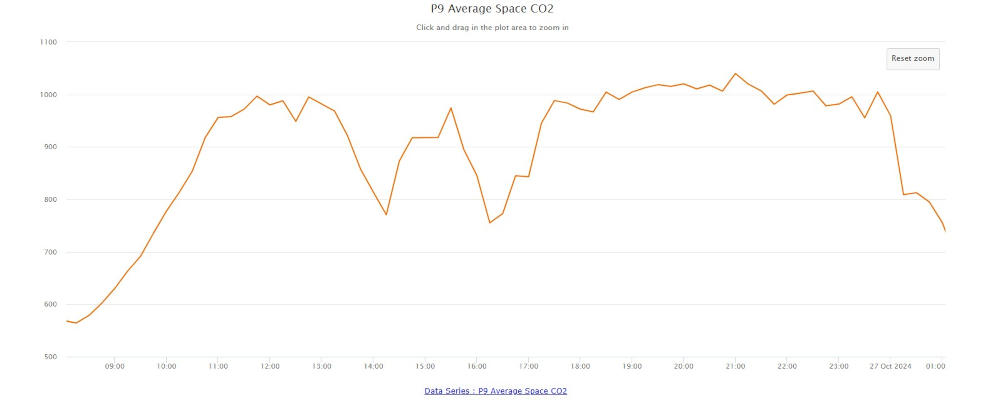

Real-time CO₂ sensors track occupancy by measuring indoor air quality. When CO₂ levels fall below the set threshold (1000 ppm), the system operates in mixing mode, optimizing temperature without additional heating. When CO₂ levels exceed the setpoint, the system switches to heat recovery mode, using the plate heat exchanger to preheat fresh air instead of activating mechanical heating or cooling.

3-Way Air Mixing Energy:

When CO₂ levels are below 1000 ppm (indicating lower occupancy), the plenum mixes a portion of return air with fresh air to regulate the inlet temperature, eliminating the need for additional Mechanical Heating/Cooling.

Plate Heat Exchanger (PHE):

The PHE captures heat from the exhaust air, transferring it to the incoming fresh air through convection and reducing the electrical load on Central Plant. This heat recovery system can recuperate between 73-80% of the energy from the extracted air.

This approach ensures that temperature is managed efficiently while minimizing energy usage, significantly reducing operational costs by prioritizing heat recovery over Central Plant.

Performance Evaluation and Data Analysis

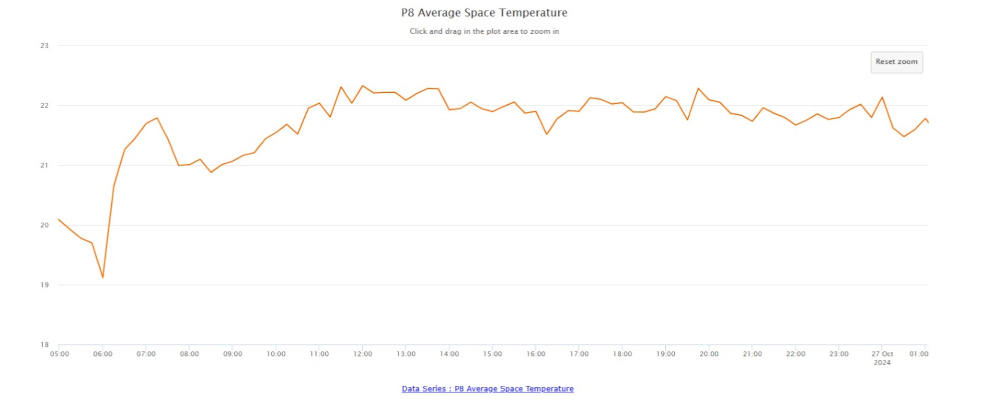

The AHU system’s performance was analysed on Saturday, October 26, 2024, focusing on energy efficiency, CO₂ levels, and temperature control. The following observations were made from this one-day analysis:

Energy Consumption:

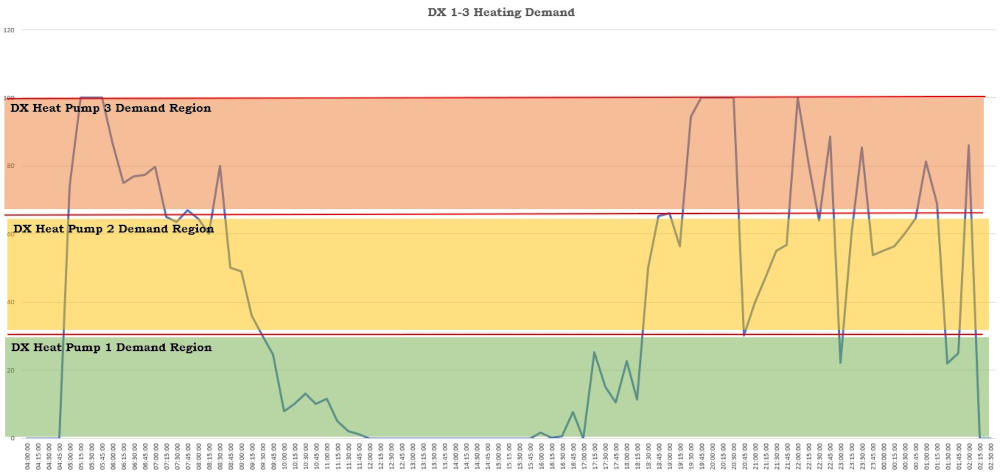

The system maintained indoor temperature primarily through heat recovery (PHE) and 3 Way Air Mixing, reducing dependency on DX heating. The plate heat exchanger and 3-way air mixing plenum managed temperature efficiently without drawing direct power, unlike traditional heat pumps, electric, or gas heaters. The average power saved over 21 hours of operation is 490kWh per day.

1

Cost Implications:

By reducing the use of Central Plant through reliance on the plate heat exchanger and 3-way air mixing plenum, the system achieved considerable energy savings. This approach led to projected reductions in operating costs for maintaining comfortable indoor conditions as described in our original case study Decarbonisation, Sustainability and Increased Profitability through Energy Recovery Air Handling Units.

3

CO₂ and Temperature Control:

The CO₂ sensors actively monitored indoor air quality throughout the day. When CO₂ levels were below the set threshold, the system operated in mixing mode, regulating temperature without additional heating or Cooling. When CO₂ levels rose above the threshold, the system automatically shifted to heat recovery mode, using exhaust air to preheat or cool incoming air. This maintained both consistent temperature and air quality.

CO2 Graph Maintained at <1000PPM

Space Temperature Graph Maintained at a Setpoint of 22Deg C.

2

Hourly Energy Savings Data

| Time | Hours | kW Saved/Hr |

| 05:00 – 12:00 | 7 | 30 |

| 12:00-19:00 | 7 | 14 |

| 19:00-02:00 | 7 | 26 |

| Total Average Power Saved | 21 hours | 490 kWh/Day |

This data highlights the significant energy savings from using the PHE and 3-Way Air Mixing plenum as a pre-heating solution, which simultaneously reduces the load on DX heat pumps.

Impact on DX Heat Pumps

The combination of a plate heat exchanger and 3-way air mixing plenum has reduced the demand on multi circuited DX heat pumps. At morning start-up, all three DX units are activated and the AHU recirculates 100% of the air via the Air Mixing plenum to quickly reach the pub’s target temperature. Once this setpoint is achieved, the AHU system maintains indoor temperature independently, without requiring mechanical heating or cooling, up until 18:00. This strategic load management further reduces energy consumption and extends the operational life of the DX units.

Get in touch

Speak with our team to ensure you receive an air handling unit that suits your needs. Call 01634 729 690 or email sales@eceuk.com.

Pay Back Period

On the busiest day of a week in winter, we achieved an energy saving of 490 kWh by utilizing the plate heat exchanger and 3-way air mixing system.

An average was taken between the air-on temperature to the PHE and the 3-way air mixing plenum, as well as an average of air-off temperature values. The Delta T was then calculated over a period of one week.

The energy saved was calculated using the Delta T value, and total saving from utilizing the plate heat exchanger and 3-way air mixing plenum for a typical week totalled 2,257.92 kWh.

Annual Savings (October to April):

With a total of 212 days in the heating season, the AHU system saves 68,382.72 kWh.

Cost Savings:

Using a standard tariff rate of £0.245 per kWh, the annual cost savings amount to £16,753.77.

This total saving, achieved by using a plate heat exchanger without factoring in the reduced load on heat pumps, electric air heater backup (EAHB), or cooling recovery mode, results in a payback period for the AHU system of approximately 3 years.

The above values are subjected to ambient temperature conditions.

Conclusion and Recommendations

The integration of a plate heat exchanger, 3-way mixing air plenum, and CO₂ monitoring system has proven highly effective in achieving the project’s energy efficiency goals. This AHU setup maintains indoor comfort while significantly reducing operational costs and energy usage by minimizing reliance on mechanical heating and cooling.

Key Benefits:

- Energy Efficiency: The system saves an average of 490kWh per day by using “free energy” from the free heating/cooling, plate heat exchanger and 3-way air mixing plenum.

- Cost Savings: Lowering the air volume to 80% of design, reduces motor electrical consumption by 50% then utilizing PHE and 3-Way Air Mixing Plenum directly translates into lower operational costs, making the AHU system both cost-effective and sustainable.

- Optimized Temperature and Air Quality Control: The CO₂ monitoring system ensures that ventilation and heating adjust dynamically based on occupancy, improving both comfort and efficiency.

- Pay Back Period: By incorporating the plate heat exchanger and 3-way air mixing plenum, the AHU setup significantly reduces energy consumption and operational costs. With an annual savings of approximately £16,753.77, the system achieves a payback period of just 3 years, making it a highly cost-effective solution for sustainable temperature control.

Get in touch

Find out more. Talk to our professional team on 01634 729 690 or email sales@eceuk.com.